Results Profile : Bulk Loading

Company Name: |

Mission Terminal Inc |

Address: |

200 Darrel Avenue, Thunder Bay, Ontario |

Application: |

Bulk Unload/Load Weigh System |

Phone: |

(905) 501-9157 |

Type of Operation: Mission Terminal provides flexible bulk loading, unloading and conditioning of various grains as well as pre-shipment bulk storage and conditioning facilities.

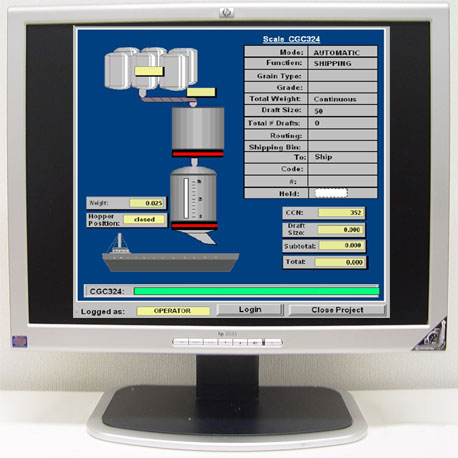

Application Details: The fully automated bulk unloading/loading system provides a centralized platform for the monitoring and control of all bulk transfers in and out of the 130 intermediate storage silos as well as corresponding conveyors, gates and motors. The system was installed to replace a hard-wired manual control system and is comprised of four sets of ‘upper garner / scale hopper’ combinations on Mettler Toledo load cells equipped with four new JagXtreme indicators, each with Allen Bradley remote I/O cards. An Allen Bradley 5/05 Ethernet PLC provides complete control of the bulk process retrofit. A 1747SN remote I/O scanner card installed in the main PLC rack polls the JagXtreme indicators for exact weight status, and downloads setpoint and tare information. The system is designed to run in full automatic mode with all four scales running independently of each other for simultaneous loading and unloading of any combination of trucks, rail cars and ships.

Operator interface is provided by two PC based workstations utilizing RS View HMI software via 19” LCD monitors and sealed mylar keyboards.

The PC workstations are networked to a third ‘view only’ workstation for use by Grain Commission personnel overseeing operations. The process is fully automated and driven from user-developed recipe screens. All operator interaction and prompts are via full colour interactive graphic displays. Any out-of-spec conditions are alarmed and adjusted before bad product can be shipped.

All data is stored to an Access database complete with weights, setpoints, operator actions, alarms, trends etc., for traceability and continuous improvement purposes. The system was designed for payback in the areas of increased throughput, consistency, conformity to spec, traceability and minimized rework.